Valve Industry

Butterfly

-Valve Seals

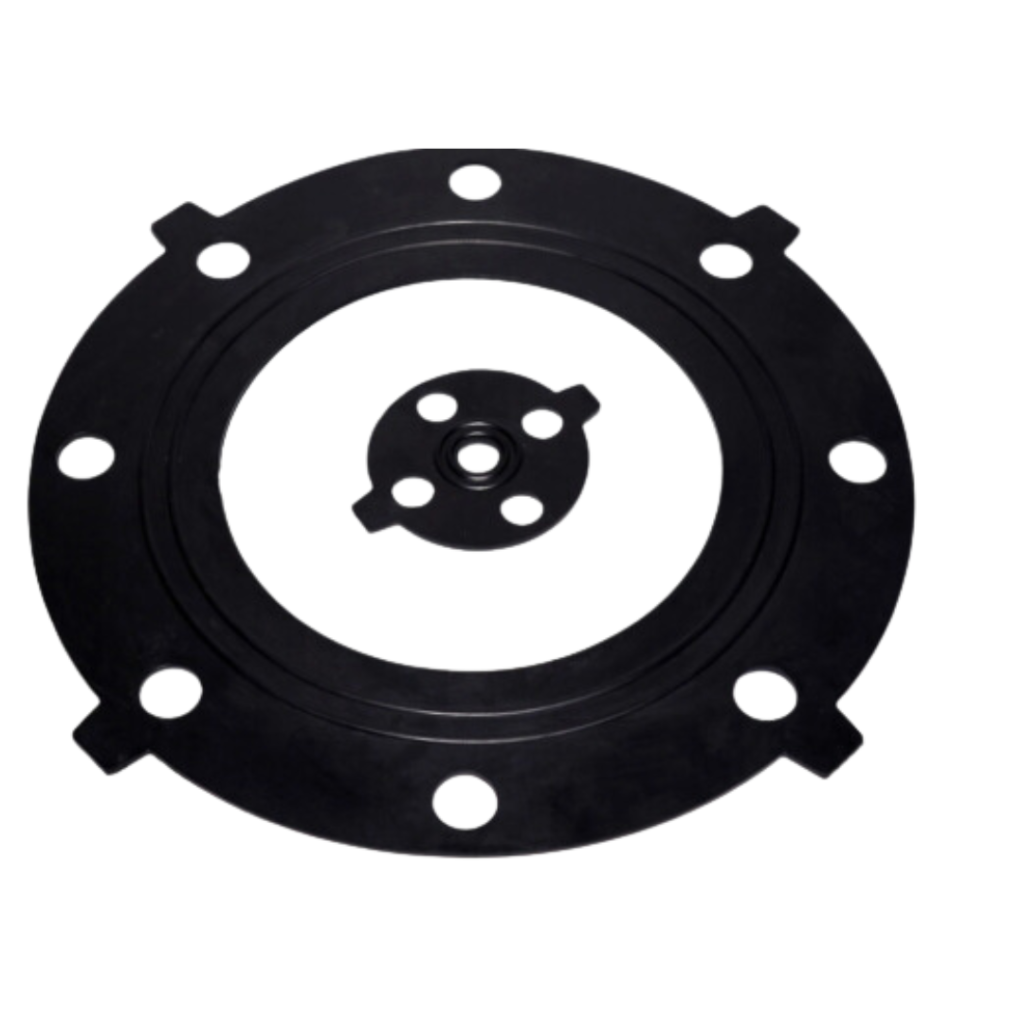

We, Crown Rubber & Plastic Products, manufactures butterfly valve seals, which is an important component for sealing all three major leakage sections: the pipe sealing area, operating shafts and flanges, flap valves, in shut-off valve, as well as disk valves.

Depending on each requirement, Crown Rubber & Plastic Products, designs In House tools, and develops and Manufactures Seals, in less lead time. To ensure, maximum performance and optimization of Valves.

Crown Rubber & Plastic Products’ Butterfly Seals, ensures high-pressing actions for maximized sealing and low–torque force required for the sealing action of Valves. We provide Butterfly seals for a minimum of 25 mm to a maximum of 950mm Diameter.

Depending on the Operating Conditions, Crown Rubber & Plastic Products manufactures seals of different materials, such as, Natural Rubber, EPDM, VITON, FKM, NITRILE, NEOPRENE, and SILICONE.

Rubber Diaphragms

Crown Rubber & Plastic Products takes pride in producing high-quality rubber diaphragms that play a crucial role in valve functionality. Our commitment to precision and efficiency ensures that our diaphragms meet tight tolerance standards and deliver maximum operating efficiency.

The diaphragm’s primary function is to create a secure seal between two chambers, guaranteeing zero leakage. We understand the critical role this component plays in various applications, and we are dedicated to manufacturing diaphragms that excel in performance.

When it comes to quality and cost-effectiveness, Crown Rubber & Plastic Products stands out as the ideal choice. We offer superior quality diaphragms at competitive prices, making us a preferred supplier for businesses looking to optimize their operations without compromising on reliability.

Our product range includes diaphragms in various sizes and shapes to accommodate diverse valve requirements. In addition to standard rubber diaphragms, we also provide options with reinforcement materials such as nylon and others, ensuring that our products can withstand demanding environments and deliver long-lasting performance.

Crown Rubber & Plastic Products is your trusted partner for top-notch diaphragms, and we are dedicated to meeting your specific needs while maintaining the highest quality standards in the industry. Whether you require standard diaphragms or custom solutions, we have the expertise and resources to deliver exceptional products that enhance the performance and reliability of your valves. Contact us today to discuss your diaphragm requirements, and experience the Crown Rubber & Plastic Products difference.

Packaging Rings

Crown Rubber & Plastic Products takes great pride in our specialization in manufacturing top-of-the-line packaging rings tailored specifically for the valve industry. Our commitment to excellence in this particular sector has earned us a reputation for delivering superior products that cater to the unique needs and demands of valve manufacturers and users.

Key highlights of our packaging rings for the valve industry:

Precision Engineering: Our packaging rings are meticulously engineered to meet the exacting standards of the valve industry. We understand the critical role these rings play in valve performance, ensuring proper sealing, protection, and longevity.

Materials Expertise: Crown Rubber & Plastic Products has extensive knowledge and experience in working with a variety of materials commonly used in the valve industry. Whether it’s rubber, plastic, or other specialized materials, we have the expertise to select and process the right materials for optimal performance.

Custom Solutions: We recognize that different valve applications may require unique packaging ring designs. Our team of experts is well-equipped to provide customized solutions to meet your specific requirements, from size and shape to material composition and reinforcement.

Durability: Our packaging rings are built to withstand the harshest operating conditions in the valve industry. They are engineered for durability, ensuring they can handle extreme temperatures, corrosive environments, and high-pressure situations without compromising performance.

Sealing Excellence: We understand that a reliable seal is essential for valve functionality. Our packaging rings are designed with a focus on creating a tight and secure seal, preventing leaks and ensuring the proper operation of valves.

Quality Assurance: At Crown Rubber & Plastic Products, quality is our top priority. Our manufacturing processes adhere to stringent quality control measures to ensure that every packaging ring leaving our facility meets or exceeds industry standards.

Competitive Pricing: We offer competitive pricing without compromising on the quality and performance of our packaging rings. We understand the importance of cost-effectiveness in the valve industry and strive to provide value to our customers.

Customer-Centric Approach: We pride ourselves on our customer-centric approach, working closely with our clients to understand their unique needs and delivering packaging ring solutions that align with their goals and expectations.

In summary, Crown Rubber & Plastic Products is your trusted partner for packaging rings in the valve industry. Our dedication to precision engineering, materials expertise, customization, durability, sealing excellence, quality assurance, competitive pricing, and a customer-centric approach makes us the ideal choice for businesses seeking reliable and high-performance packaging rings for their valve applications. Contact us today to discuss your specific packaging ring requirements and experience the superior quality and service we provide.

O rings

CROWN RUBBER AND PLASTIC PRODUCTS (CRPP) is a trusted manufacturer known for providing high-quality O-rings that play a critical role in the automotive industry. Our O-rings are precision-engineered to meet the exacting standards of the automotive sector, offering easy assembly and extended functional life.

Here’s a detailed technical explanation of our O-rings and their capabilities:

Zero Leakage and Maximum Sealing: CRPP O-rings are designed to create a tight and reliable seal, ensuring zero leakage in various mediums. This sealing excellence is vital in automotive applications, where fluids and gases must be contained without any compromise.

Wide Temperature Range: Our O-rings are engineered to withstand extreme temperatures, making them versatile for automotive applications. They can perform effectively within a temperature range from -16 degrees Celsius to +200 degrees Celsius. This temperature tolerance ensures consistent performance in various climate conditions and engine environments.

Material Variety: CRPP offers a wide variety of O-ring materials to cater to different Valve Industry needs:

Natural Rubber: Provides excellent flexibility and resilience, making it suitable for sealing applications in various automotive components.

EPDM (Ethylene Propylene Diene Monomer): Known for its exceptional resistance to weathering, ozone, and heat, EPDM O-rings are commonly used in automotive cooling systems and weather seals.

Nitrile (Buna-N): Nitrile O-rings are oil-resistant and ideal for sealing automotive fuel systems, hydraulic systems, and lubrication systems.

Neoprene: Neoprene O-rings offer good resistance to oils, chemicals, and UV exposure, making them suitable for a range of automotive applications.

Silicon: Silicon O-rings exhibit excellent temperature resistance and flexibility. They are commonly used in automotive engine gaskets and seals.

Viton: Viton O-rings are known for their superior chemical resistance and high-temperature performance, making them suitable for demanding automotive applications involving aggressive fluids and high temperatures.

FKM (Fluoroelastomer): FKM O-rings excel in high-temperature and chemical-resistant applications, making them ideal for use in automotive engines and transmission systems.

Each material choice offers specific advantages, allowing CRPP to provide O-rings tailored to the exact requirements of various automotive components and systems.

In conclusion, CRPP’s O-rings are meticulously designed and manufactured to meet the stringent demands of the automotive industry. With their zero leakage guarantee, wide temperature range capabilities, and a variety of material options including Natural Rubber, EPDM, Nitrile, Neoprene, Silicon, Viton, and FKM, our O-rings are the ideal choice for ensuring reliability and longevity in automotive applications. Contact us today to discuss your specific O-ring needs and experience the superior quality and performance that CRPP O-rings provide in the automotive sector.

Rubber Gaskets

Crown Rubber & Plastic Products stands as a premier supplier within the valve industry, specializing in the precise manufacturing of top-tier gaskets and seals. Our distinguished reputation for excellence has been meticulously cultivated through our steadfast dedication to offering tailored manufacturing solutions that precisely meet the rigorous demands of valve applications.

Our core objective is to consistently exceed the expectations of our valued customers by delivering gaskets and sealing products engineered with the valve industry’s specific requirements in mind. We are unwavering in our commitment to providing competitive pricing, ensuring punctual delivery, and delivering unparalleled customer service that distinguishes us as a leader in the field.

Crown Rubber & Plastic Products is resolutely devoted to precision and accuracy, pledging to meet all of your blueprint specifications and tolerance requirements with the utmost diligence. Our focal point revolves around the meticulous crafting of gaskets and sealing solutions that seamlessly align with the intricate and distinctive needs and challenges that typify the valve industry. This unwavering dedication solidifies our standing as your trusted and dependable partner in the manufacturing of valve components, consistently delivering products that elevate the performance and reliability of valve systems to unparalleled levels of excellence.

Rubber Seating

Crown Rubber & Plastic Products is a recognized expert in the precise fabrication of rubber seating components designed specifically for valve applications. Our extensive knowledge and expertise in this domain have positioned us as a trusted manufacturer of high-quality rubber seating solutions tailored to meet the exacting requirements of valve systems.

Here’s a more detailed technical explanation of our rubber seating for valves:

Material Expertise: Crown Rubber & Plastic Products excels in working with a wide range of rubber materials, carefully selecting the most suitable compounds for valve seating applications. These materials are chosen for their exceptional durability, resilience, and resistance to factors such as wear, corrosion, and temperature variations.

Molded Precision: Our rubber seating components are precisely molded to ensure uniformity and consistency in shape and dimensions. This precision is essential for creating a reliable and secure seal within valve systems.

Optimized Geometry: The geometry of our rubber seating is optimized to enhance sealing performance. This includes factors such as the shape, thickness, and contour of the seating, all of which are meticulously engineered to provide a perfect fit within the valve assembly.

Resilience: Our rubber seating is designed to maintain its elasticity and resilience over time, ensuring long-lasting performance. This resilience allows the seating to effectively conform to irregularities in valve surfaces, further enhancing the sealing capability.

Chemical Compatibility: We take into account the compatibility of the rubber materials with the fluids or gases being handled by the valve. Our rubber seating is selected or customized to withstand exposure to various chemicals without degradation.

Temperature Resistance: Crown Rubber & Plastic Products’ rubber seating components are engineered to endure extreme temperature conditions, including both high and low temperature ranges. This capability ensures reliable sealing performance across diverse environments.

Quality Assurance: Quality is at the core of our manufacturing processes. We maintain stringent quality control measures to guarantee that every rubber seating component we produce meets or exceeds industry standards. This commitment to quality ensures the reliability and longevity of our products.

Custom Solutions: We understand that different valve applications may require unique seating solutions. Our team of experts is equipped to provide customized seating designs to accommodate specific valve requirements, from size and shape to material composition and reinforcement.

In summary, Crown Rubber & Plastic Products is your premier partner for the manufacturing of rubber seating components for valves. Our in-depth expertise in materials, precision molding, geometry optimization, resilience, chemical compatibility, temperature resistance, quality assurance, and customization allows us to deliver seating solutions that excel in performance and reliability within valve systems. Contact us today to discuss your specific rubber seating needs, and experience the superior quality and service that define our products in the valve industry.

Other Molded

-Rubber Products

Crown Rubber & Plastic Products is a distinguished manufacturer specializing in the production of an extensive range of molded rubber products that are designed to cater to the diverse needs of the valve industry. Our comprehensive expertise in rubber molding allows us to create products of varying shapes, sizes, and materials, ensuring they seamlessly integrate into valve systems while delivering exceptional performance and reliability.

Here’s an elaborative overview of our capabilities and the diverse range of molded rubber products we offer for the valve industry:

Customization Expertise: At Crown Rubber & Plastic Products, we understand that valve applications can vary widely. That’s why we excel in providing customized solutions. We have the capability to tailor our molded rubber products to meet specific requirements, whether it’s for gaskets, seals, diaphragms, bellows, grommets, or any other rubber component used in valve systems.

Materials Versatility: We work with an extensive range of rubber materials, including natural rubber, EPDM, Nitrile, Neoprene, Silicon, Viton, FKM, and more. This materials versatility allows us to select the most suitable compound for the intended application, considering factors such as temperature resistance, chemical compatibility, and durability.

Precision Molding: Our state-of-the-art manufacturing processes ensure precision in molding. Each product is carefully crafted to meet exacting specifications, guaranteeing uniformity in shape and dimensions. This precision is vital for maintaining the integrity of valve systems.

Quality Assurance: Quality is at the core of our manufacturing ethos. We adhere to rigorous quality control protocols to ensure that every molded rubber product we produce adheres to industry standards. This commitment to quality guarantees the reliability and longevity of our products.

Functionality Optimization: We take into account the functional requirements of each rubber component. Whether it’s creating a perfect seal, providing flexibility, withstanding extreme temperatures, or offering resistance to chemicals, our products are engineered to optimize functionality within valve applications.

Multi-purpose Applications: Our molded rubber products find application in various valve components, such as valve seats, gaskets, stem seals, check valve components, and more. Their versatility allows them to perform effectively across different valve types and sizes.

Rapid Prototyping: We offer rapid prototyping services to assist in the development and testing of new rubber components, helping our customers refine their designs and achieve optimal performance in valve applications.

In summary, Crown Rubber & Plastic Products is your trusted partner for high-quality, customized molded rubber products in the valve industry. Our proficiency in customization, materials versatility, precision molding, quality assurance, functionality optimization, and rapid prototyping allows us to deliver solutions that enhance the performance and reliability of valve systems. Contact us today to discuss your specific requirements, and experience the exceptional quality and service that define our products for the valve industry.